Details of our quality control

We carefully inspect every one of our products regardless of whether they are produced internally or by another company. We set strict quality standards for each product, and we are proud of our thorough quality control system.

In every single product, we use dress form mannequins to check that our stones swing for at least ten seconds.

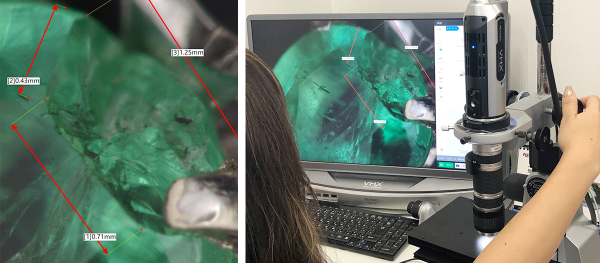

The prong, back, and sides of the frame of completed tennis chains are all checked by microscope for defects in the adhesion surface, distortion, broken parts, and scratches/dents, etc. Completed products are also put through a tension test, and only products that exceed our strict standard values are shipped.

通常は顕微鏡での検品が主ですが、200倍のマイクロスコープを使って検品し、画像を保存して記録。クロスフォー社では、石についた傷の範囲、そのクラックがどこでどのように入ったのかまで詳細に検証します。

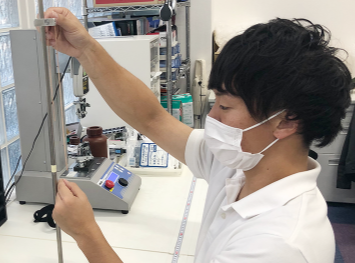

弊社の特許技術であるEXC-LOCK™に使用しているばねの強度や反発テストを実施。

テニスチェーンの枠のねじれがないかを一つ一つ検査します。

テニスチェーンの枠の強度を検査。枠のサイズや地金の種類によって合格基準を設けて検査をかけます。

Crossfor digitalizes all products that become defective during the manufacturing process. When a product from outsourced companies has a defect, Crossfor asks for a correction and makes a request for the submission of an improvement plan. As a result, we have successfully been able to decrease our product defect rate. Crossfor manufactures products that satisfy our customers with this thorough quality control.